Email Us

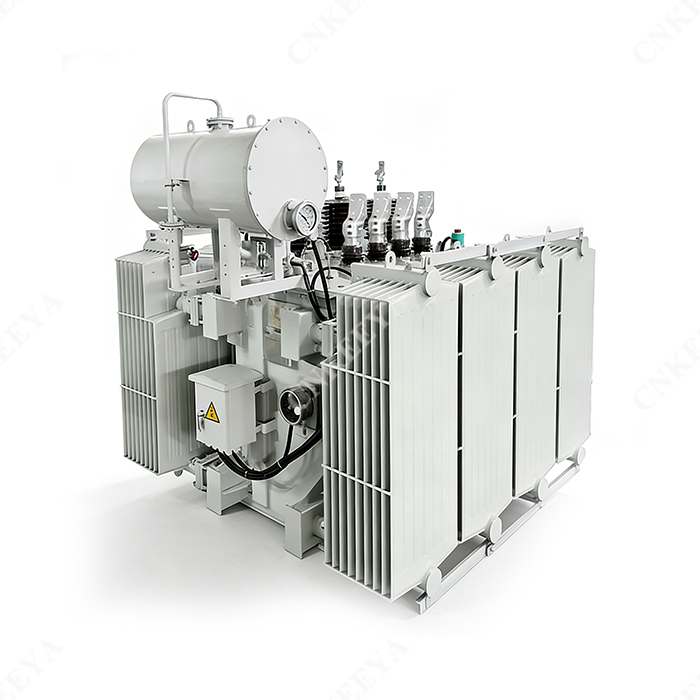

Three phase 800KVA 20KV 420V Oil-immersed Distribution transformer

CNKEEYA, a leading manufacturer, introduces the Three Phase Oil Immersed Distribution Transformer, offering a perfect blend of cutting-edge technology and cost-effectiveness. Committed to delivering high-quality products at competitive prices, CNKEEYA stands as a reliable source for cost-efficient solutions in the realm of three-phase oil-immersed distribution transformers. Partner with us to access top-notch manufacturing expertise, budget-friendly options, and excellence in the field of distribution transformers. CNKEEYA is your trusted partner for innovative solutions that meet your needs without compromising on quality or affordability.

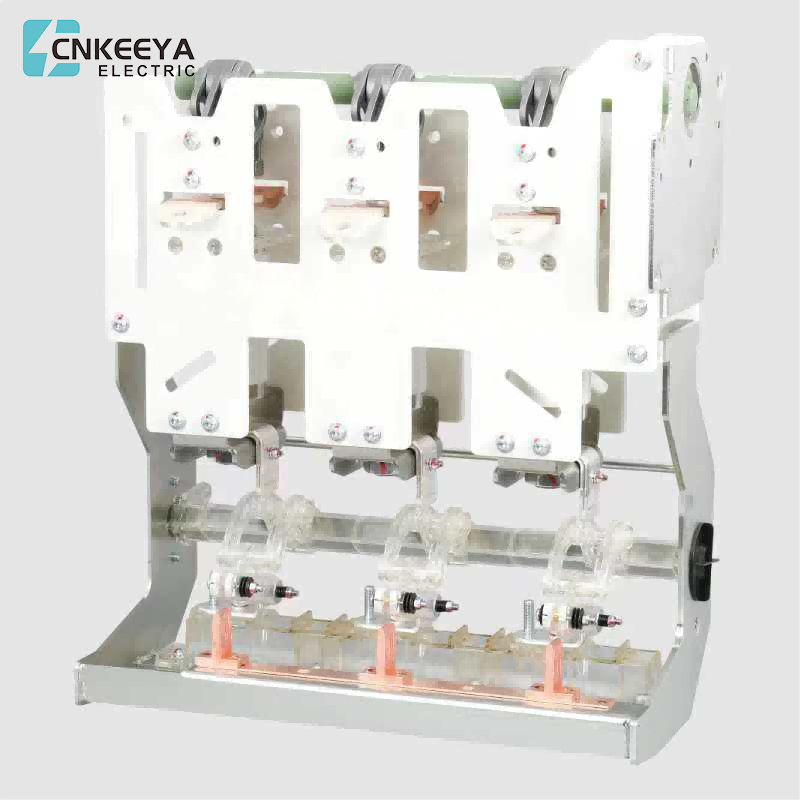

CNKEEYA manufactures three phase oil immersed distribution transformers featuring an innovative insulation structure, significantly enhancing their short-circuit resistance capabilities. The core is meticulously crafted from premium-grade cold-rolled silicon steel sheets. Both high and low voltage windings are meticulously assembled using top-tier oxygen-free copper wire, employing a multi-layered cylinder configuration. All fasteners undergo a specialized anti-loosening treatment. These transformers exhibit exceptional traits, boasting high efficiency and minimal energy loss. This translates to substantial savings in power consumption and operational expenses, underscoring their substantial societal benefits. They represent a cutting-edge, nationally endorsed high-tech product.

Operating Environment

1. Highest ambient temperature: +40℃

2. Lowest ambient temperature: -25℃

3. Elevation: below 1000 meters

4. Highest monthly average relative humidity: 90% (at 20℃)

5. Installation location: suitable for installation in areas free from fire or explosion hazards, significant pollution, chemical corrosion, or excessive vibration, whether indoors or outdoors.

Product Characteristics

1. The transformer core is constructed using high-grade, imported cold-rolled silicon steel sheets, significantly reducing both no-load losses and currents. This also ensures a tight core binding for enhanced compactness and reduced noise levels.

2. The high and low voltage windings are meticulously wound with oxygen-free copper. For transformers with capacities of 500KVA and below, a double-layer, four-helix structure is employed for the low-voltage winding, while the high-voltage winding adopts a multi-layered cylinder configuration.

3. The transformer's winding connections adhere to the Dyn11 standard, effectively minimizing the impact of harmonic waves on the power grid and enhancing overall power supply quality.

4. The transformer is designed with a fully-sealed structure, extending its operational lifespan and eliminating the need for suspended core usage and maintenance.

5. The measured noise level falls below established standards, ensuring a quieter and more efficient operation.

Technical parameter

|

6KV to 35KV three Phase Oil Immersed Distribution Power Transformer |

|||||||||

|

|

|

|

Weight (kg) |

(mm) |

|||||

|

Rated Capacity |

|

(75) |

No-load current |

|

|

|

(L) |

(W) |

(H) |

|

(kVA) |

No-load |

Load |

% |

Machine |

Oil |

Gross |

Dimension |

||

|

50 |

0.21 |

1.21 |

2 |

195 |

205 |

590 |

1000 |

950 |

1450 |

|

100 |

0.29 |

2.02 |

1.8 |

320 |

240 |

790 |

1080 |

1000 |

1600 |

|

125 |

0.34 |

2.38 |

1.7 |

395 |

270 |

950 |

1100 |

1030 |

1630 |

|

160 |

0.36 |

2.83 |

1.6 |

460 |

285 |

1020 |

1130 |

1060 |

1630 |

|

200 |

0.43 |

3.33 |

1.5 |

555 |

325 |

1170 |

1190 |

1060 |

1670 |

|

250 |

0.51 |

3.96 |

1.4 |

630 |

340 |

1340 |

1260 |

1160 |

1700 |

|

315 |

0.61 |

4.77 |

1.4 |

720 |

400 |

1530 |

1280 |

1240 |

1790 |

|

400 |

0.73 |

5.76 |

1.3 |

830 |

490 |

1780 |

1960 |

880 |

1900 |

|

500 |

0.86 |

6.93 |

1.2 |

930 |

510 |

1960 |

2020 |

940 |

1920 |

|

630 |

1.04 |

8.28 |

1.1 |

1085 |

600 |

2290 |

2070 |

1010 |

2010 |

|

800 |

1.23 |

9.9 |

1 |

1270 |

660 |

2640 |

2240 |

1040 |

2150 |

|

1000 |

1.44 |

12.15 |

1 |

1495 |

735 |

3100 |

2300 |

1200 |

2150 |

|

1250 |

1.76 |

14.67 |

0.9 |

1775 |

830 |

3630 |

2450 |

1280 |

2250 |

|

1600 |

2.12 |

17.55 |

0.8 |

2140 |

935 |

4235 |

2220 |

1510 |

2350 |

|

2000 |

2.61 |

21.5 |

0.8 |

2535 |

1035 |

4910 |

2310 |

1740 |

2440 |

|

2500 |

3.15 |

23 |

0.8 |

3140 |

1190 |

5840 |

2370 |

1840 |

2490 |

|

(Note): (Tapping range of high voltage) ±5%; ±2×2.5%. power transformer oil distribution transformer |

|||||||||

-

Address

No. 68, Wei No.19 Road, Yueqing Economic Development Zone, Yueqing City, Wenzhou City, Zhejiang Province,China

-

Tel

-

E-mail

Contact Us

No. 68, Wei No.19 Road, Yueqing Economic Development Zone, Yueqing City, Wenzhou City, Zhejiang Province,China

Copyright © 2025 Zhejiang Hanya Electric Appliance Co., Ltd. All Rights Reserved.