Send Inquiry

Contact Info

-

Address

No. 68, Wei No.19 Road, Yueqing Economic Development Zone, Yueqing City, Wenzhou City, Zhejiang Province,China

-

Tel

-

E-mail

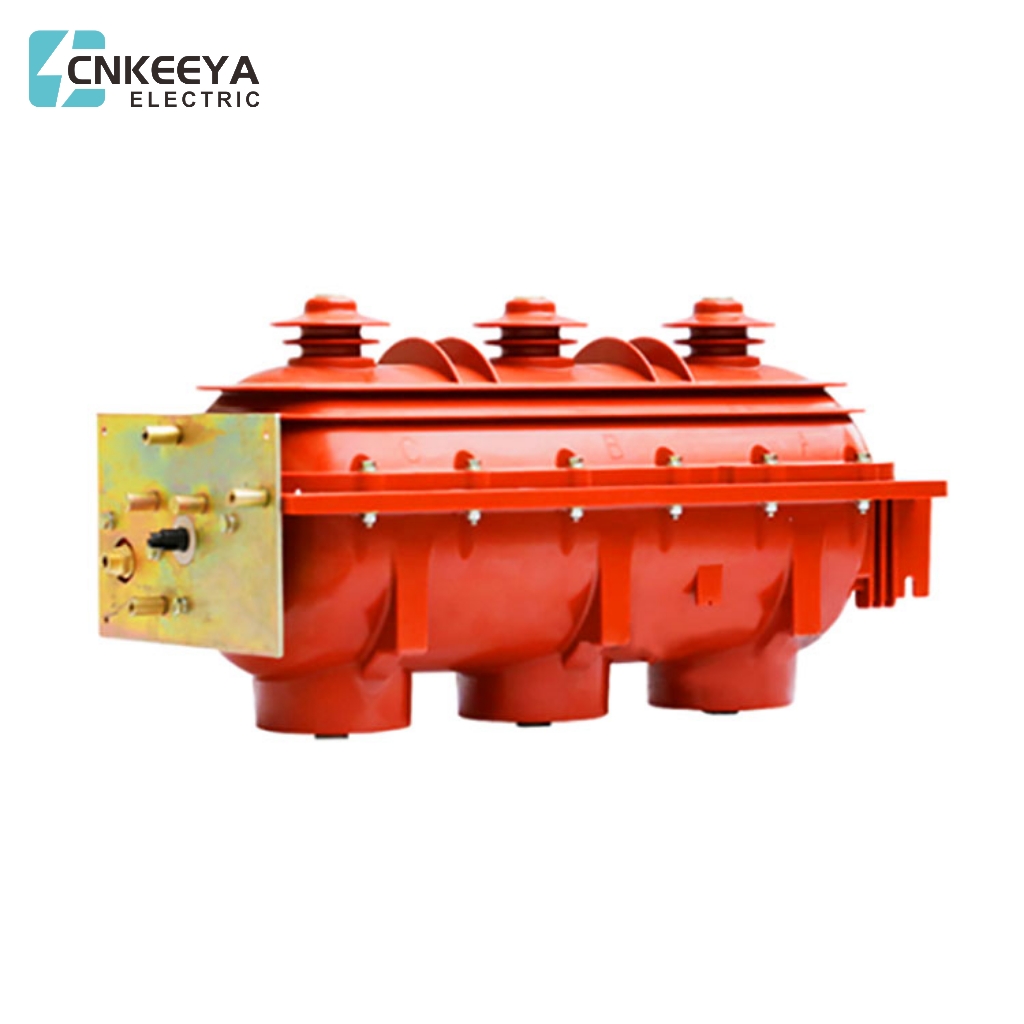

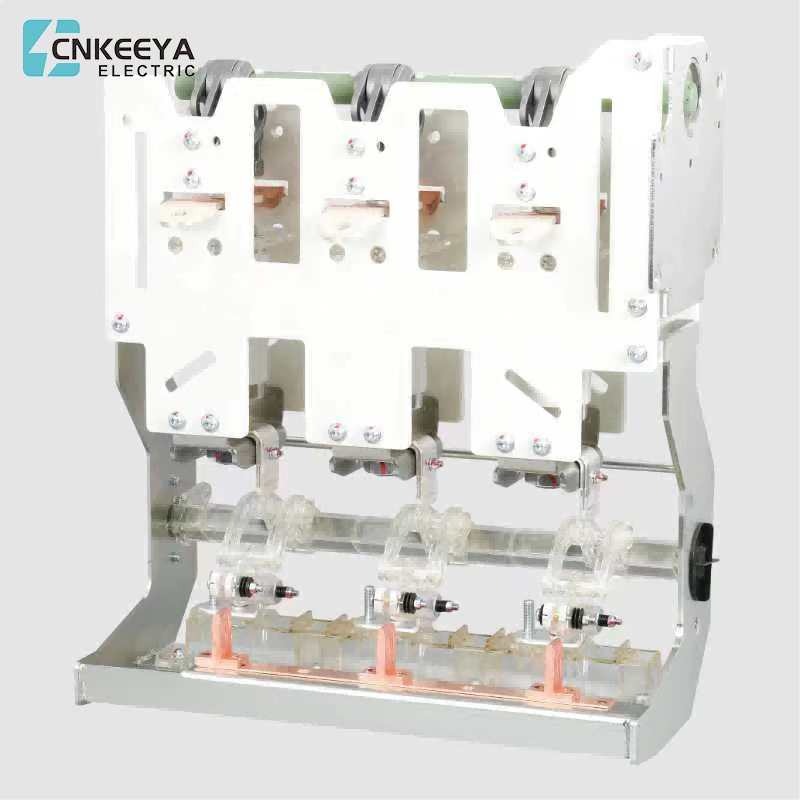

For inquiries about Distribution Cabinet Shell, Circuit Breakers, Switchgear or price list, please leave your email to us and we will be in touch within 24 hours.