Email Us

Deepening North American Market! Our Company's U.S. Low-Voltage Switchgear Project Successfully Completed

Recently, the low-voltage switchgear project customized by our company for a well-known U.S. enterprise has successfully passed acceptance and been completed. The delivered low-voltage switchgear products strictly comply with the U.S. UL 891 standard and National Electrical Code (NEC). With outstanding technical performance, reliable safety guarantees and customized solutions, the project has won high recognition from the customer, laying a solid foundation for the company to further expand the North American market.

Accurately Meeting Demands, Customized Solutions Demonstrate Strength

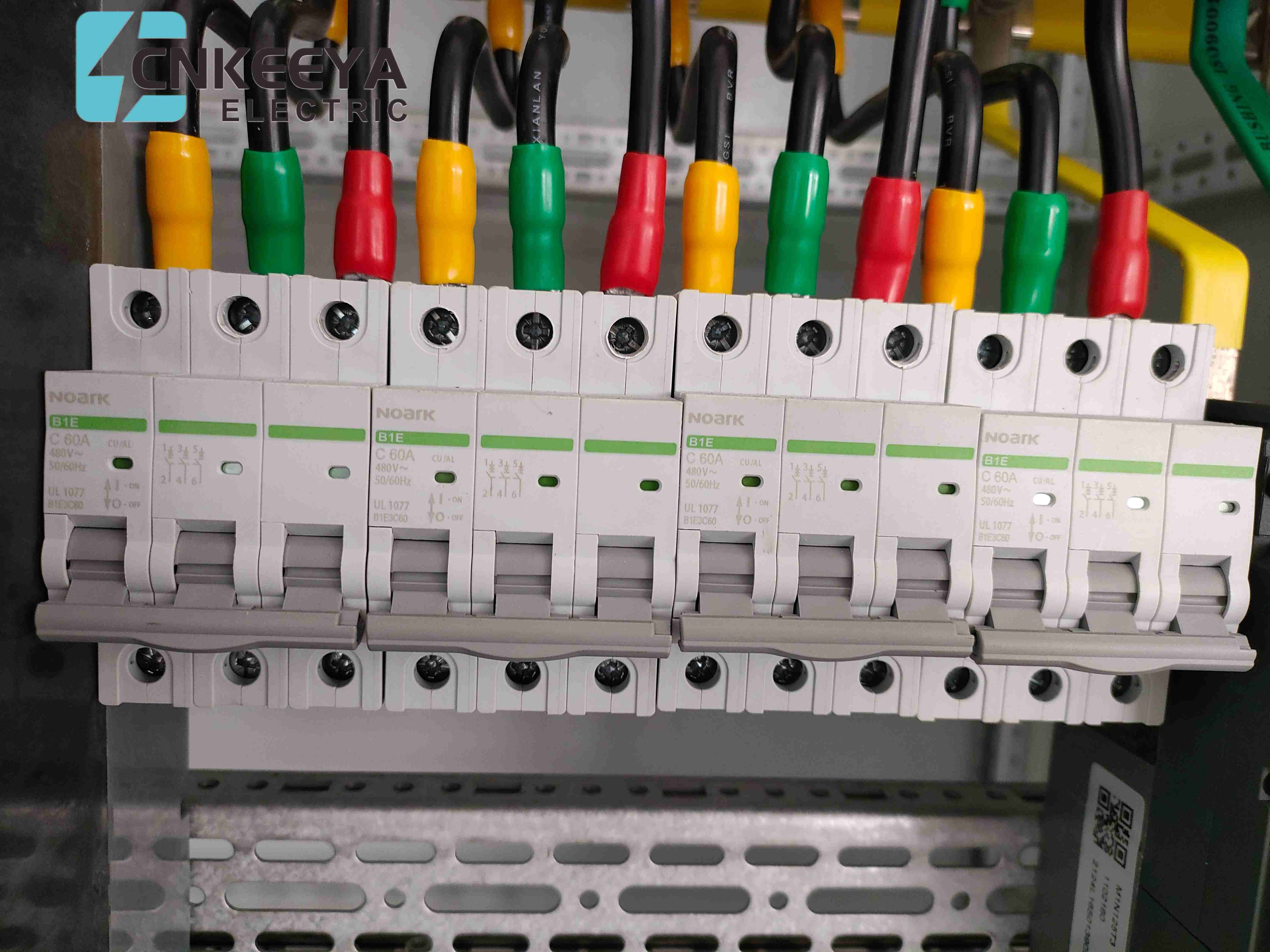

It is understood that the cooperating U.S. customer has a profound accumulation in the industrial field and has extremely strict requirements on the safety, stability and intelligence of low-voltage power distribution equipment. In response to the customer's needs, our company established a special R&D team to conduct in-depth research on North American market standards and industry characteristics, and finally determined a solution centered on withdrawable low-voltage switchgear. This solution not only meets the key indicators required by the UL 891 standard for switchboard structural strength, electrical clearance, temperature rise control, etc., but also has passed certifications such as the UL 508 industrial control equipment standard and UL 67 switchboard standard, ensuring that the products fully comply with North American market access regulations.

Outstanding Technical Highlights, Forging High-End Power Distribution EquipmentThe low-voltage switchgear products delivered this time have achieved multiple breakthroughs in technology, demonstrating the company's strong R&D and manufacturing capabilities.

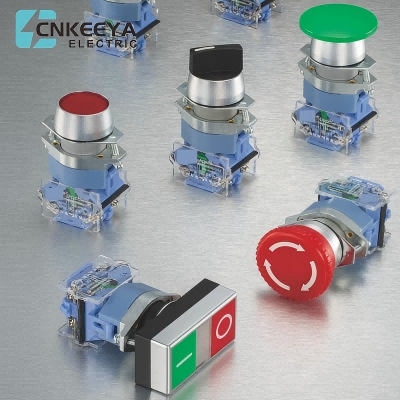

Structural Innovation, Space Utilization Rate Leading the Industry: Adopting the modular design concept and drawing on the structural characteristics of internationally advanced MNS withdrawable switchgear, 24 MCC control units are reasonably arranged in a limited space. The cabinet is divided into three independent areas: front left, front right and rear. Each area can be opened independently for operation, separated by steel plates and flame-retardant plastic modules, which effectively improves the safety of equipment operation and maintenance convenience. At the same time, in view of the operating habits in the North American market, the floor-mounted circuit breaker design is innovatively adopted, which reduces the equipment height by 30%, avoids the operation risk of high center of gravity of the traditional middle-mounted circuit breaker trolley, and greatly improves the safety of on-site operation and maintenance.

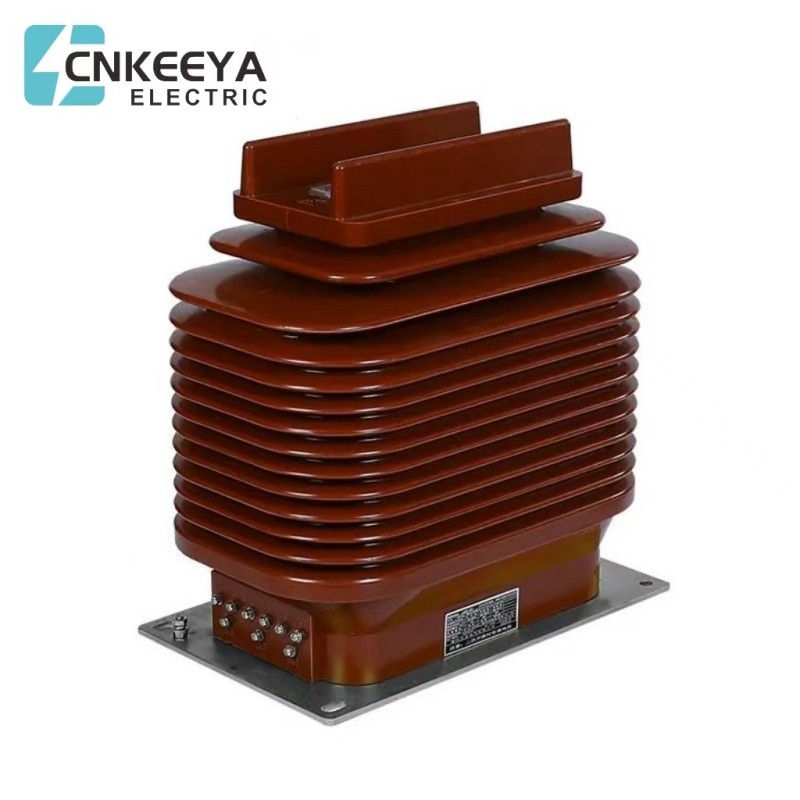

Intelligent Upgrade, Realizing Full-Cycle Status Management: Equipped with an advanced intelligent monitoring system, integrating temperature monitoring and partial discharge detection functions, and supporting the IEC61850 communication protocol. Operation and maintenance personnel can grasp the equipment operation parameters in real time through remote terminals, predict potential faults in advance, and the fault prediction accuracy rate reaches more than 92%. A high-precision voltmeter and multi-functional changeover switch are installed on the cabinet surface, which cooperates with the upper control circuit composed of Schneider dual power supplies to ensure the accuracy and stability of power distribution.

Safety Protection, Multiple Guarantees for Absolute Safety: Strictly following the requirements of UL standards, the busbar system uses high-purity copper materials, with rated currents covering 600A-2000A specifications, and short-circuit current withstand capacity reaching 65kA, which can ensure equipment safety under extreme working conditions. The withdrawable unit is set with three clear operating positions: connection, test and separation. The mechanical interlocking mechanism realizes the safety protection that the withdrawable unit cannot move when the circuit breaker is closed. The insulating material is made of UL 94 V-0 grade flame-retardant material, which fully meets the strict requirements for electrical safety in the North American market.

Overcoming Difficulties, Promoting Project Implementation EfficientlySince the project was launched, various departments of the company have worked closely together to overcome multiple challenges such as cross-time zone communication and standard differences. The R&D team spent three months completing the entire process from scheme design to prototype testing, and successively passed multiple strict tests such as temperature rise test, dielectric strength test and short-circuit current test in UL-recognized laboratories; the production department activated the automated production line to realize the efficient connection between precision processing of cabinet frames and component assembly, ensuring product quality consistency; the project team followed up the installation and commissioning throughout the process, and optimized the scheme in a timely manner according to the actual on-site working conditions, and finally completed the project delivery 15 days earlier than the contract stipulated time.

Overcoming Difficulties, Promoting Project Implementation EfficientlySince the project was launched, various departments of the company have worked closely together to overcome multiple challenges such as cross-time zone communication and standard differences. The R&D team spent three months completing the entire process from scheme design to prototype testing, and successively passed multiple strict tests such as temperature rise test, dielectric strength test and short-circuit current test in UL-recognized laboratories; the production department activated the automated production line to realize the efficient connection between precision processing of cabinet frames and component assembly, ensuring product quality consistency; the project team followed up the installation and commissioning throughout the process, and optimized the scheme in a timely manner according to the actual on-site working conditions, and finally completed the project delivery 15 days earlier than the contract stipulated time.

High Recognition from Customers, Opening a New Chapter in the North American Market"The low-voltage switchgear products delivered by your company have shown excellent quality in both performance tests and practical applications. Their modular design and intelligent monitoring functions perfectly meet our production needs. Especially the accurate grasp of U.S. standards makes us full of confidence in future cooperation." The person in charge of the U.S. customer's project said at the acceptance ceremony. The successful completion of this project marks that our company's low-voltage switchgear products have the core competitiveness to enter the high-end North American market. The company will take this opportunity to further deepen the North American market, expand diversified application scenarios such as industry, data centers and commercial buildings, and provide better power distribution solutions for global customers.

In the future, our company will continue to increase R&D investment, focus on international market standards and industry technology trends, promote the upgrading of low-voltage power distribution equipment towards intelligence and greenization, and strive to establish a benchmark image of Chinese brands in the global power equipment field.

- Warm Celebration for the Successful Power-on of Our Company's Medium-Voltage 13.8KV Switchgear Project in the United States

- Our Company's Nigeria Gas-Insulated Cabinet Project Successfully Completed and Shipped

- Our Company's Gas-Insulated Switchgear Powers Mexican Power Project, Empowering National Grid Upgrade

- Four KYN61 cabinets from the company were successfully loaded and shipped to assist in the construction of power projects for Ukrainian customers

- 12KV CCV altogether box type 304 gas box inflation cabinet was successfully delivered to customers in Türkiye

- DELIVERY OF 13.8kV KYN28 SWITCHGEAR FOR AMERICAN DATA CENTER PROJECT

Contact Us

No. 68, Wei No.19 Road, Yueqing Economic Development Zone, Yueqing City, Wenzhou City, Zhejiang Province,China

Copyright © 2025 Zhejiang Hanya Electric Appliance Co., Ltd. All Rights Reserved.